“Mahan Rah Roshan” industrial group is one of the prominent manufacturers in the field of designing and manufacturing high quality concrete production machinery, which includes dry batching machines, wet batching machines, mobile or mobile batching machines, and portable batching machines

batching plant (concrete central station)

Dry batching

All the ingredients of concrete, except water, are carefully weighed into the truck mixer, and then water is added to the materials, and the mixing process is carried out by the truck mixer during transfer to the project

Wet Batching

All the materials and ingredients of standard concrete are transferred into the mixer and combined, because of the better mixing, the concrete has a better quality.

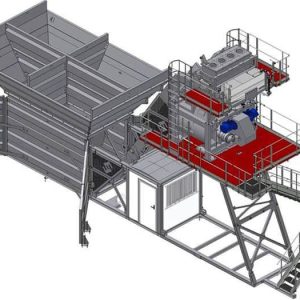

Among the types of batching plants, we can mention fixed-mobile batching plants that are made in “Mahan Rah Roshan Industrial Group”

Batching plant (portable)

The advantages of this type of batching are in easy transportation and not needing scattered foundation, not needing a lot of space and installation in one day.

All the equipment of the machine is placed on a chassis and it has the ability to work with all mixers including drum, one shaft mixer, mixer, twin shaft, pan mixer, etc. and all the equipment can be controlled with a fully digital and automatic control unit

List of portable batching plant equipment

1. Material weighing feeder with pneumatic jacks, pneumatic valves, pneumatic control unit, material weighing load cells, material weighing funnel, material valves, material vibrators, etc.

2. Conveyor belt under the feeder with gearbox, electric motor, roller, rubber, conveyor chassis and back and front rollers.

3. Mother conveyor for transferring materials from feeder to mixer along with rollers, rubber, electric motor, gearbox and hubs.

4. Screws for carrying cement from the silo to the scale and from the scale to the mixer, dry hopper with electric gearbox and other equipment.

5. Scale for weighing cement with valve jack and cement weight load cells.

6. Connex and control panel that make up the control unit and have the ability to work both manually and automatically.

7. The silo above the feeder, which stores chickpeas, almonds, sand, etc.

8.Compressed air production unit for pneumatic equipment.

9. Water supply system with water pump and water meter.

10. The mixer inside the patching system.

11. Dry funnel in dry batches.

12. Spare parts and fasteners and bases.

13. Cement silo

14. Other special requirements

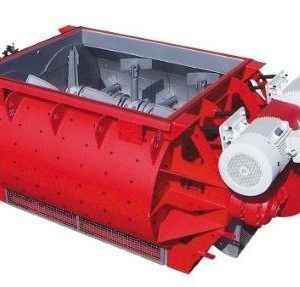

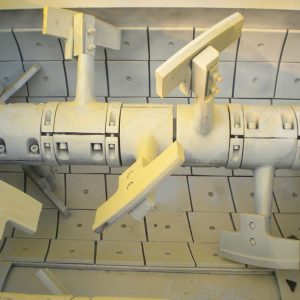

Twin shaft mixer

The best type of concrete mixer used in batching plant, which is also used in construction projects around the world, is a twin-shaft or two-axis mixer, like two single-shaft mixers placed side by side.

Twin shaft mixers can be installed on all types of batching plants (central concrete plant) and table and block making machines for concrete parts.

Twin shaft mixer has the ability to produce more concrete in less time than other common mixers.

The twin shaft mixer has the ability to mix and mix up to 95% homogeneity. With two axes for mixing and multi-dimensional arms, this mixer has the ability to mix materials or materials completely, and by using a layer of anti-wear steel as body protection, it makes the body very resistant and wear-resistant.By using this mixer, you can increase the strength of your concrete several times, which saves cement consumption.

Twin shaft mixer can produce the best percentage of material mixing in low time.

With its high mixing power, this mixer is capable of complete mixing in 30 seconds, emptying in 4 seconds, and loading in the shortest possible time.

This device is produced in different capacities in “Mahan Rah Roshan Industrial Group”

Portable batching plant

One of the most popular batching plants in the field of concrete and construction is a portable batching plant with the ability to move easily and install quickly. In this type of batching plant, there is no need to separate parts and reassemble it, and the device can be transported and produce concrete in an integrated manner.

One of the features of the portable batching plant of Mahan Rah Roshan Industrial Group is its compact and fully connected design.Other features of this device include the following:

Easy to move with only one trolley

The possibility of setting up in minimal space

Automatic or manual control

Digital weighing system

Equipped with a folding conveyor belt for easy transportation

High speed of work

No need to implement foundation

Quick and easy maintenance

High build quality for long term use

Portable batching is more suitable for companies that intend to use this device in various short-term projects.

scale

In the concrete mixing plan, cement plays a decisive role in the strength of concrete after drying, and in fact, the adhesive material of concrete (sand) is its cement, and it must be according to the standard.The weighing method is used to measure the amount of cement used, which is the most accurate method for weighing cement using digital load cells.

Cement scales can be manufactured in a wide range of capacities and are designed and produced according to needs

It has three load cells with international standards

High volume compartment

Strong structure without vibration

Double sided hopper

When designing the batching plant line in a set where the system has a mixer, there are cases when it is necessary to load concrete both wet and dry (without mixing), in these cases, a system is added between the mixer and the main conveyor belt to easily add these places.

This system will be different from the type of mixer, which is separate from the conveyor belt or part of the conveyor belt, and a separate conveyor belt can be used for this purpose

Screw conveyor (cement spiral)

In the batching plant complex, cement screw is used to transfer cement from the silos to the scale and after weighing from the scale to the mixer (track mixer or fixed mixers).

Cement screws are made in diameters of (10, 8, 6) inches depending on the amount of cement required for each batch.

SN system or fluctuation

Variety in length up to 12 meters

Internal blades of ST52 steel

With round flanges

conveyor belt

In the concrete batching plant complex, after storing and weighing the materials, a conveyor belt is used to transfer the items to the mixer.

Conveyor belts are generally made in U-shaped, V-shaped and flat shapes (profiles), and U and V-shaped models are used for moving bulk materials without a specific shape, this type of conveyor belt is also used in batching plant.

The size (rubber width and form angle) of the conveyors will be different according to the type of material, which is obtained during the design stages using relevant calculations