The equipment of fixed asphalt plant of Mahanrah Roshan design with the simultaneous capability of fully automatic, semi-automatic and manual in the capacities of 80 tons to 240 tons per hour and the mobile or mobile (wheeled) asphalt plant with the ability to install and move quickly in capacities of 120 and 160 tons per hour and produce asphalt according to the standards of the publications and instructions of the Ministry of Road Construction

cold silo

The capacity is 10 cubic meters and can be increased due to the high strength of the chassis and body

Automatic and manual adjustable rubber feeders

You have a microphone and switches to show whether the silo is full or empty

Easy tape adjustment

Impact rollers

All cut rollers

Replaceable bearing

High safety for the workforce

Conveyor and feed transfer

Drying oven (dryer)

In two gear models and 4 gearboxes

H beam chassis with very high strength

All internal blades and blades are bolted and replaceable

Double wall with 100 density stone wool insulation

The inner wall is made of stainless steel or aluminum sheets

Protective rims

Anti-wear alloy rims and rollers

Bolted rims

The unique design of internal buckets and as a result a significant reduction in fuel consumption

Better heating or so-called core cooking of materials

Material elevator (material elevator-filter elevator-cement elevator)

Roller or wheels made of anti-wear cast iron alloy

Steel chains and crepes by hot forging method and resistant to heat, wear and stress

Internal bearing without falling filler

Chain self-adjustment system

Spoon with double edges

Equipped with a locking system to prevent the spoons from returning during a sudden power outage

Turbojet burner

Three triple-dual-single-burner models (gas-diesel-diesel)

Thermal Ranch 3 to 24 million kcal

The ability to start and control the flame fully automatically or manually

Flame condition viewing system

Complete mixing of fuel and air and no raw combustion

Automatic temperature system according to the material coming out of the dryer on the set desired degree

Flame cover and flame spreader made of refractory steels 41-48

Gas line with high reliability factor

Sarand

Uniform vibration system

Ability to change the vibration range

The body and floors are made of resistant tensile steels

Against failure and tension

Designed with 5 or 6 different granulations

Quick and easy replacement of laces (stretchable text)

Non-clogging of mesh springs due to its new design

Two-axis vibration system with permanent oil

Easy access to the floors

It has dust and moisture ventilation channels

Warm bucket silage

Uniform vibration system

Ability to change the vibration range

The body and floors are made of resistant tensile steels

Against failure and tension

Designed with 5 or 6 different granulations

Quick and easy replacement of laces (stretchable text)

Non-clogging of mesh springs due to its new design

Two-axis vibration system with permanent oil

Easy access to the floors

It has dust and moisture ventilation channels

Filler-cement weighing system and other additives (filler scale)

Material weighing system (material scale)

Bitumen weighing system (bitumen scale)

Simultaneous asphalt boiler (mixer)

Double-walled with 50 density stone wool insulation and temperature maintenance for a long time

Ability to design in different capacities and desired number

Equipped with three valves

No remaining asphalt after high slope discharge

The channel system in the middle of the mixer washing and no dust entry

The result of washing the mixer

The ability to place a load cell to show the amount of asphalt weight in the silo

Silo of overflowing and out-of-size materials

Dust collector (multi cyclone)

Bag filter (bag filter)

Fabrics with high heat resistance and waterproof and moisture resistant

No cake and dust around the bag

Metal baskets with thick and plated bars

Air return design and prevent bags from tearing

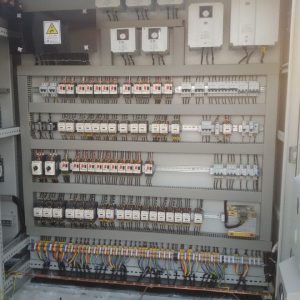

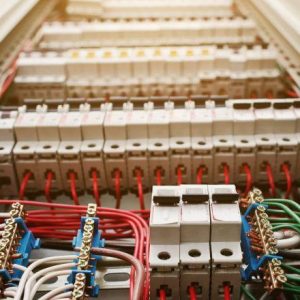

PLC intelligent protection system

Environmentally certified

Proven cleaning capability of 99% at high working pressure

Can be used in various mineral industries such as asphalt, gypsum, cement, tiles, micronized powders, pharmaceutical and food industries.

Centrifugal fan (exhaust fan or exofan)

Bitumen Flask

Strong steel body

It has a double-wall bitumen pump and is insulated with 50 density stone wool

The second wall is made of galvanized steel sheets

Internal hot oil coil with high oil volume

Bitumen heat retention for a long time

It has a filling valve and a mechanical bitumen level indicator

Equipped with indicators and thermocouples for temperature display

Double wall bitumen pump floating extraction system

Hot oil pot or furnace (oil heater)

Capacity of 300-500-700 and one million kilocalories

Manisman’s fire-resistant pipe material

Optimized against heat loss with special design

Automatic ventilation system

Fully automatic thermal burner

insulated with double-layer stone wool with a density of 100 cm

It has an intelligent security system with high safety

Faucets with high working class

Equipped with oil level switch, expansion source and water trap